Korea Advanced Institute of Science and Technology (KAIST, President Lee Kwang-hyung) announced on the thirteenth that it plans to operate the ‘Manufacturing AI Metaverse Factory Experience Center’ on the ‘2023 Hannover Messe 2023’ held in Hannover, Germany from the seventeenth to the twenty first.

KAIST plans to form a collaboration consortium with UNIST, Hanyang University, Digiforet, ABH, and KEMP centered on the Manufacturing AI Big Data Center throughout the institution to organize a booth for the ‘Manufacturing AI Metaverse Factory’ experience hall and welcome visitors. .

Visitors can wear virtual reality (VR) equipment and experience the specified experience from stage 1 to stage 3 as in the event that they were inside the positioning.

In Step 1, you’ll hear the strategy of collecting, storing, and analyzing manufacturing data, and you may practice it instantly. It is a very useful course for beginners to grasp the production process. It could actually be used for job training for brand new employees of producing firms.

Within the second stage, it is feasible to observe and manipulate factory facilities at a distance through the metaverse. The German booth provides the experience of operating the Ulsan plant, which is about 9,000 km away.

If manufacturing AI routinely detects a dangerous situation and sends an alarm, employees can access the metaverse space even in the event that they are removed from the positioning, take protected motion and stop accidents.

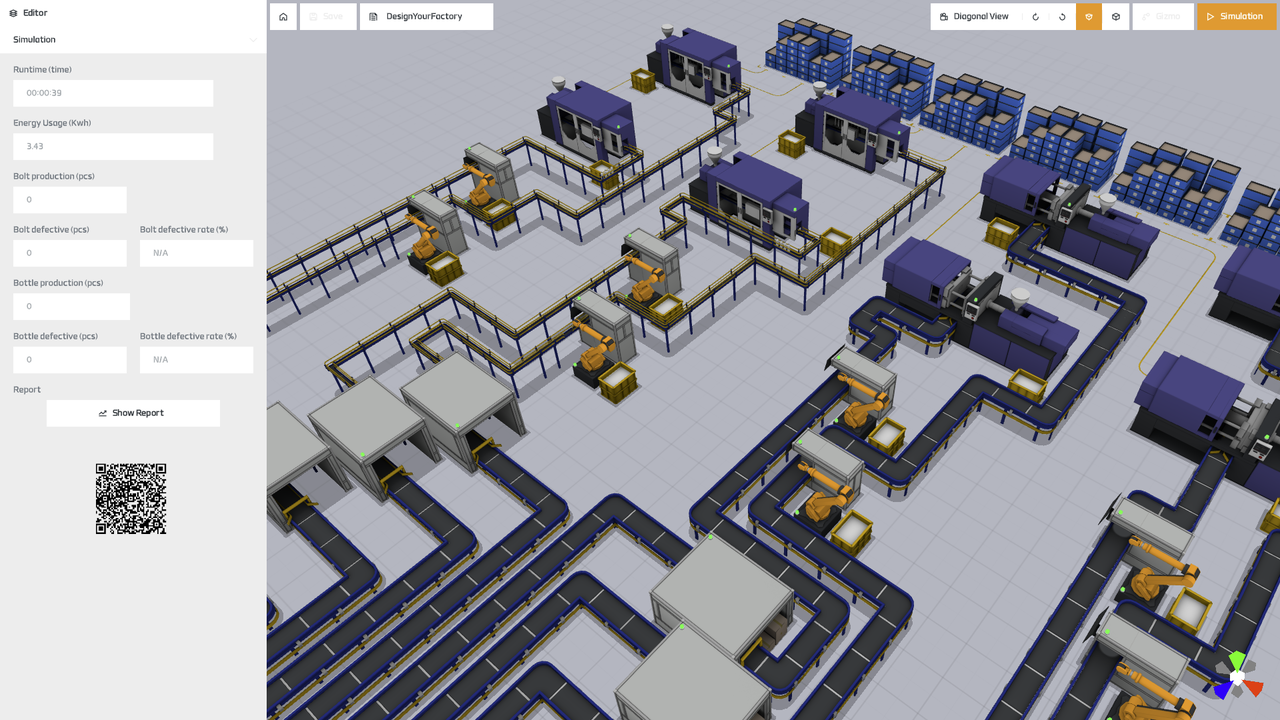

Within the third stage, you may freely arrange the facilities on the metaverse, which is strictly similar to the manufacturing site. This permits employees to use various arrangements of apparatus and autonomously judge convenience and efficiency to comprehend the optimal work flow.

Iljoong Kim, head of the Manufacturing AI Big Data Center at KAIST, said, “It is going to be a spot to deliver solutions with AI technology to the challenges facing the worldwide manufacturing industry.” We are going to construct the complete factory with technology and develop it in order that it might be checked prematurely with augmented reality (VR).”

Hannover Messe is the world’s largest trade fair, celebrating its 76th anniversary this yr. This yr, with the theme of ‘Industrial Transformation-Making the Difference’, greater than 4,000 firms comparable to Autodesk, Bosch, Microsoft, and Siemens participated, providing the most recent information within the fields of mechanical engineering, electrical engineering, energy, software, and IT. exhibit your skills

AI Times Reporter Cho Ye-ju joyejuoffice@gmail.com