Manufacturing -specialized artificial intelligence (AI) firms have emphasized price competitiveness and security to extend on -site introduction. The AI & Big Data Show, which will probably be held at COEX on the eleventh, conducted product demonstrations and intensive consulting.

Within the manufacturing sector, ▲ defect detection of products using vision AI ▲ work site safety control solution, and ▲ detection and forestry preservation solution using mechanical equipment time series data.

Within the case of Vision AI solutions, it showed an approach to cut back investment costs within the means of image data.

RTM introduced the AI Vision Inspection Platform ‘Hubble’ and explained that it increased efficiency in the information labeling process.

Hubble consists of a ‘engine’ that learns and distributes inspection models, an edge that works with facilities, and a dashboard that integrates data. Amongst them, when learning data on the engine, the product image automated the means of recognizing and learning the defect.

Consequently, the inspector airborne could be greatly reduced to 83%and the price of introduction could be reasonably offered.

Machine process management solutions could be reduced by combining with sensor products.

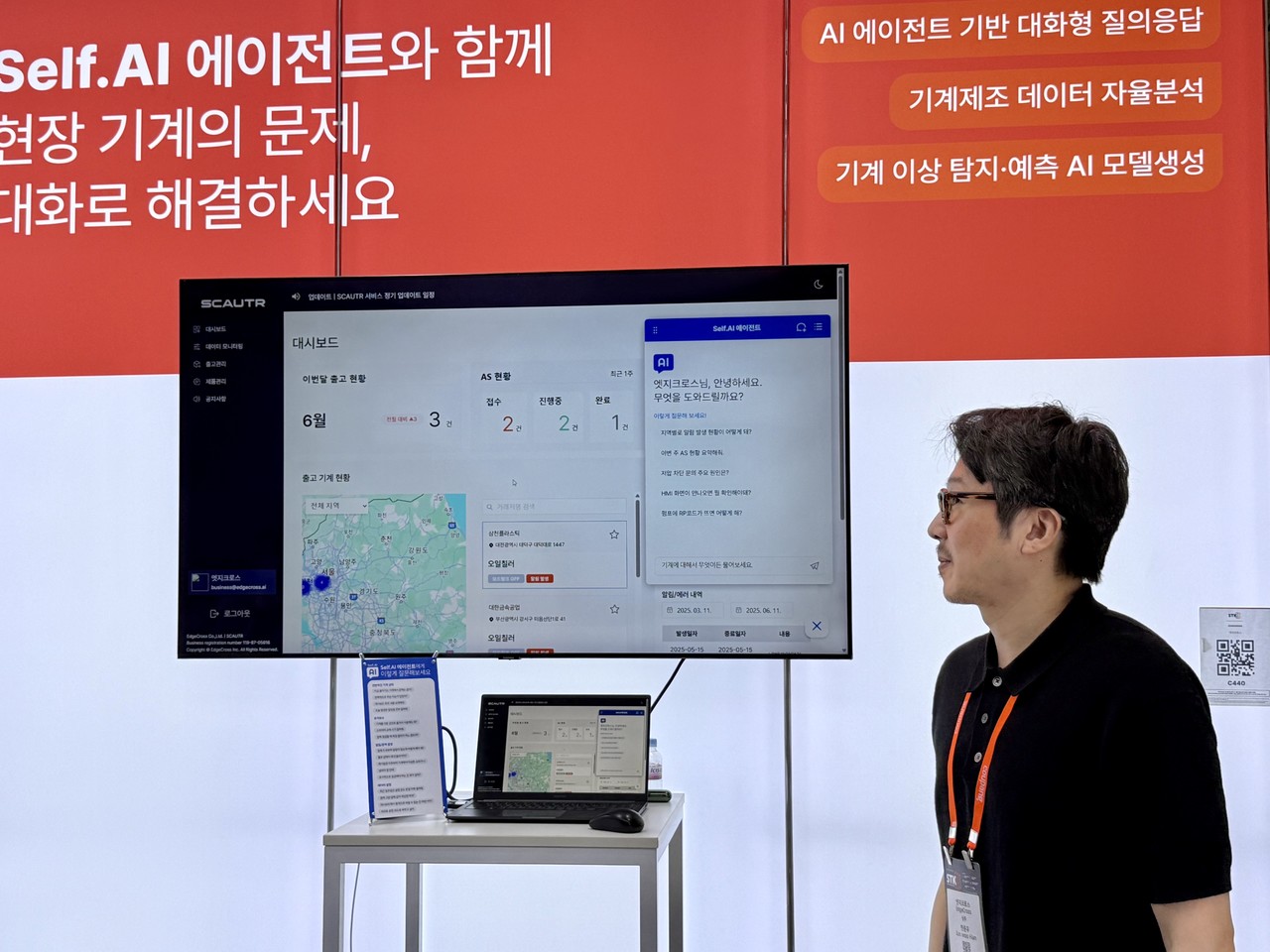

Smart Machine specialized edgross introduced sensors that collect data resembling temperature and humidity, sound, and vibration, and ‘Self AI Agent’ specialized in machine management.

In line with officials, when purchasing sensor equipment, the self -AI agent was provided at a low price of 10,000 won per 30 days, so it reduced the burden on firms that were hesitant to introduce because of cost problems.

The explanation for specializing in the value is that almost all manufacturers are sensitive to prices. In line with data surveyed by SME Ben, the proportion of SMEs within the manufacturing sector as of 2022 is 97.4%. Because of this, the introduction of AI within the domestic manufacturing industry remains to be within the early stages.

An edgross official said, “Most SMEs are concerned with the introduction of AI, but they often feel burdened with investment costs.” “Due to this fact, now we have proposed a self -AI agent for patrons who’ve already purchased sensor equipment,” he said.

He also added that the entry barrier must be introduced to introduce an AI agent, and continuous data accumulation will probably be optimized for the commercial field.

Unlike domestic manufacturing AI firms, global firms SAP has made strength and security as a strength.

SAP and Dongkuk Systems have arrange a producing execution system (MES) system that uses cloud for domestic firms that have to operate several factories overseas. The 2 firms have partnerships in April last yr and are expanding their cloud conversion business models to global business within the manufacturing sector.

An official of Dongkuk Systems said, “In Korea, there may be a requirement for firms that want to examine the manufacturing data of varied overseas factories at a look to forestall concerns concerning the leakage of fair data, but it surely is suggesting that the cloud and the establishment environment are enhanced while strengthening the safety and introducing the cloud’s benefits.”

As well as, “in the long run, the price of using the AI model will probably be reduced, and it should have benefits by way of costs since it offers various price policies in accordance with the client’s situation.”

Meanwhile, the AI & Big Data Show, which shows the domestic AI industry trend at a look, will probably be held at COEX until 5:00 on the thirteenth.

By Park Soo -bin, sbin08@aitimes.com