chain is a goal-oriented network of processes and stock points that delivers finished goods to stores.

Imagine a luxury fashion retailer with a central distribution chain that delivers to stores worldwide (the USA, Asia-Pacific, and EMEA) from a warehouse situated in France.

When the store 158 situated at Nanjing West Road (Shanghai, China) needs 3 leather bags (reference AB-7478) by Friday, a distribution planner creates a replenishment order.

This order is shipped to the warehouse for preparation and shipping.

From this point on, the distribution planner loses direct control.

The shipment’s fate will depend on a posh distribution chain involving IT, warehouse, and transportation teams.

Nevertheless, if anything goes fallacious, the planner is the one who has to clarify why the shop missed sales as a result of late deliveries.

Each step is usually a source of delays.

Why only 73% of shipments were delivered on time last week?

If shipments miss a cutoff time, this may occasionally be as a result of late order transmission, excessively long preparation time, or a truck that departed the warehouse too late.

Unfortunately, static dashboards should not at all times sufficient to search out root causes!

Subsequently, planners typically analyse the information (manually using Excel) to discover the foundation causes of every failure.

In my profession, I actually have seen entire teams spend dozens of hours per week manually crunching data to reply basic questions.

Essentially the most complicated task in Supply Chain Management is coping with people!

This can be a critical role because managers will at all times attempt to shift responsibility amongst themselves to cover their very own teams.

Because root cause evaluation is step one in continuous improvement, we must develop an answer to support planners.

You won’t ever solve operational problems if you happen to cannot find the foundation causes.

Subsequently, I desired to experiment with how an AI Agent can support distribution planning teams in understanding supply chain failures.

I’ll ask the AI agent to resolve real disputes between teams to find out whether one team is misinterpreting its own KPIs.

The thought is to make use of the reasoning capabilities of Claude models to discover issues from timestamps and boolean flags alone and to reply natural-language questions.

We wish the tool to reply open questions with data-driven insights without hallucinations.

What’s the responsibility of warehouse teams in the general performance?

These are actual questions that distribution planning managers must answer on a day-to-day basis

This agentic workflow uses the Claude Opus 4.6 model, connected via an MCP Server to a distribution-tracking database to reply our questions.

I’ll use a real-world scenario to check the power of the agent to support teams in conducting analyses beyond what static dashboards can provide:

- Solve conflicts between teams (transportation vs. warehouse teams)

- Understand the impact of cumulative delays

- Assess the performance of every leg

Understand Logistics Performance Management

We’re supporting a luxury fashion retail company with a central distribution warehouse in France, delivering to stores worldwide via road and air freight.

The International Distribution Chain of a Fashion Retailer

A team of supply planners manages store inventory and generates replenishment orders within the system.

From this, a cascade of steps until store delivery

- Replenishment orders are created within the ERP

- Orders are transmitted to the Warehouse Management System (WMS)

- Orders are prepared and packed by the warehouse team

- Transportation teams organise every thing from the pickup on the warehouse to the shop delivery via road and air freight

On this chain, multiple teams are involved and interdependent.

Our warehouse team can start preparation only after orders are received within the system.

Their colleagues within the transportation team expect the shipments to be ready for loading when the truck arrives on the docks.

This creates a cascade of potential delays, especially considering cut-off times.

- Order Reception: if an order is received after 18:00:00, it can’t be prepared the day after (+24 hours in LT)

- Truck leaving: if an order isn’t packed before 19:00:00, it can’t be loaded the identical day (+24 hours in LT)

- Arrival at Airport: in case your shipment arrives after 00:30:00, it misses the flight (+24 hours LT)

- Landing: in case your flight lands after 20:00:00, it is advisable wait an additional day for customs clearance (+24 hours LT)

- Store Delivery: in case your trucks arrive after 16:30:00, your shipments can’t be received by store teams (+24 hours LT)

If a team experiences delays, they’ll affect the remaining of the chain and, eventually, the lead time to deliver to the shop.

Hopefully, we’re tracking each step within the delivery process with timestamps from the ERP, WMS, and TMS.

For every element of the distribution chain, we’ve:

- The timestamp of the completion of the duty

- A goal timing for the duty completion

For the step linked to a cut-off time, we generate a Boolean Flag to confirm whether the associated cut-off has been met.

Problem Statement

Our distribution manager doesn’t need to see his team manually crunching data to know the foundation cause.

This shipment has been prepared two hours late, so it was not packed on time and had to attend the subsequent day to be shipped from the warehouse.

This can be a common issue I encountered while answerable for logistics performance management at an FMCG company.

I struggled to clarify to decision-makers that static dashboards alone cannot account for failures in your distribution chain.

In an experiment at my startup, LogiGreen, we used Claude Desktop, connected via an MCP server to our distribution planning tool, to support distribution planners of their root-cause analyses.

And the outcomes are quite interesting!

How AI Agents Can Analyse Supply Chain Failures?

Allow us to now see what data our AI agent has available and the way it could possibly use it to reply our operational questions.

We put ourselves within the shoes of our distribution planning manager using the agent for the primary time.

Distribution Planning

We took one month of distribution operations:

- 11,365 orders created and delivered

- From December sixteenth to January sixteenth

For the input data, we collected transactional data from the systems (ERP, WMS and TMS) to gather timestamps and create flags.

A fast Exploratory Data Evaluation shows that some processes exceeded their maximum lead-time targets.

On this sample of 100 shipments, we missed the loading cutoff time for not less than six orders.

This means that the truck departed the warehouse en path to the airport without these shipments.

These issues likely affected the remaining of the distribution chain.

What does our agent have available?

Along with the lead times, we’ve our boolean flags.

These booleans measure if the shipments passed the method on time:

- Transmission: Did the order arrive on the WMS before the cut-off time?

- Loading: Are the pallets within the docks when the truck arrived for the pick-up?

- Airport: The truck arrived on time, so we wouldn’t miss the flight.

- Custom Clearance: Did the flight land before customs closed?

- Delivery: We arrived at the shop on time.

For barely lower than 40% of shipments, not less than one boolean flag is about to False.

This means a distribution failure, which could also be attributable to 1 or more teams.

Can our agent provide clear and concise explaination that will be used to implement motion plans?

Allow us to test it with complex questions.

Test 1: A distribution planner asked Claude concerning the flags

To familiarise herself with the tool, she began the discussion by asking the agent what he understood from the information available to him.

This demonstrates that my MCP implementation, which uses docstrings to define tools, conforms to our expectations for the agent.

Test 2: Difficult its methodology

Then she asked the agent how we might use these flags to evaluate the distribution chain’s performance.

In this primary interaction, we sense the aptitude of Claude Opus 4.8 to know the complexity of this exercise with the minimal information provided within the MCP implementation.

Testing the agent with real-world operational scenarios

I’m now sufficiently confident to check the agent on real-world scenarios encountered by our distribution planning team.

They’re answerable for the end-to-end performance of the distribution chain, which incorporates actors with divergent interests and priorities.

Allow us to see whether our agent can use timestamps and boolean flags to discover the foundation causes and arbitrate potential conflicts.

Nevertheless, the actual test isn’t whether the agent can read data.

The query is whether or not it could possibly navigate the messy, political reality of distribution planning, where teams blame each other and dashboards may obscure the reality.

Let’s start with a difficult situation!

Scenario 1: difficult the local last-mile transportation team

In accordance with the information, we’ve 2,084 shipments that only missed the most recent boolean flag Delivery OnTime.

The central team assumes that is as a result of the last-mile leg between the airport and the shop, which is under the local team’s responsibility.

For instance, the central team in France is blaming local operations in China for late deliveries in Shanghai stores.

The local manager disagrees, pointing to delays on the airport and through customs clearance.

Allow us to ask Claude if it could possibly find who is correct.

Claude Opus 4.6 here demonstrates precisely the behaviour that I expected from him.

The agent provides nuance by comparing the flag-based approach to static dashboards with an evaluation of durations, because of the tools I equipped it with.

This states two things:

- Local team’s performance (i.e. Airport -> Store) isn’t worse than the upstream legs managed by the central team

- Shipments leave the airport on time

This means that the problem lies between takeoff and last-mile store delivery.

This is strictly what Claude demonstrates below:

The local team isn’t the one reason behind late deliveries here.

Nevertheless, they still account for a big share of late deliveries, as explained in Claude’s conclusion.

What did we learn here?

- The local team responsible still needs to enhance its operations, but it surely isn’t the one party contributing to the delays.

- We want to confer with the Air Freight team the variability of their lead times, which affects overall performance, even after they don’t miss the cut-off times.

In Scenario 1, the agent navigated a disagreement between headquarters and an area team.

And it found that either side had a degree!

But what happens when a team’s argument relies on a fundamental misunderstanding of how the KPIs work?

Scenario 2: a fight between the warehouse and the central transportation teams

We’ve got 386 shipments delayed, where the only flag at False is Loading OnTime.

The warehouse teams argue that these delays are as a result of the late arrival of trucks (i.e., orders prepared and prepared on time were awaiting truck loading).

Is that true? No, this claim is as a result of a misunderstanding of the definition of this flag.

Allow us to see if Claude can find the best words to clarify that to our distribution planner.

Because we shouldn’t have a flag indicating whether the truck arrived on time (only a cutoff to find out whether it departed on time), there may be some ambiguity.

Claude may also help us to make clear that.

For this query, Claude exactly did what I expected:

- It used the tool to analyse the distribution of lead times per process

- Explained the best significance of this flag to the distribution planner in the important thing insight paragraph

Now that the distribution planner knows that it’s fallacious, Claude will provide the best elements to answer the warehouse team.

Unlike in the primary scenario, the remark (or query) arises from a misunderstanding of the KPIs and flags.

Claude did an amazing job providing a solution that’s able to share with the warehouse operations team.

In Scenario 1, each teams were partially right. In Scenario 2, one team was simply fallacious.

In each cases, the reply was buried in the information, not visible on any static dashboard.

What can we learn from these two scenarios?

Static dashboards won’t ever settle these debates.

They show what happened, not why, and never who’s truly responsible.

Distribution planners know this. That’s why they spend dozens of hours per week manually crunching data to reply questions their dashboards can’t.

Somewhat than attempting to construct a comprehensive dashboard that covers all scenarios, we are able to deal with a minimal set of boolean flags and calculated lead times to support custom analyses.

These analyses can then be outsourced to an agent, comparable to Claude Opus 4.6, which can use its knowledge of the information and reasoning skills to offer data-driven insights.

We are able to even use it to generate interactive visuals to convey a selected message.

Within the visual above, the thought is to point out that relying solely on Boolean flags may not fully reflect reality.

Flag-Based attribution was probably the source of quite a bit conflicts.

All of those visuals were generated by a non-technical user who communicated with the agent using natural language.

That is AI-powered analysis-as-a-service for supply chain performance management.

Conclusion

Reflecting on this experiment, I anticipate that agentic workflows like this may replace an increasing variety of reporting projects.

The advantage here is for the operational teams.

They shouldn’t have to depend on business intelligence teams to construct dashboards and reports to reply their questions.

Can I export this PowerBI dashboard in Excel?

These are common questions it’s possible you’ll encounter when developing reporting solutions for supply chain operations teams.

It’s because static dashboards won’t ever answer all of the questions planners have.

With an agentic workflow like this, you empower them to construct their very own reporting tools.

The distribution planning use case focused on diagnosing past failures. But what about future decisions?

We applied the identical agentic approach, using Claude connected via MCP to a FastAPI optimisation engine, to a really different problem: Sustainable Supply Chain Network Design.

The thought here was to support supply chain directors of their redesign of the network within the context of the sustainability roadmap.

Where should we produce to attenuate the environmental impact of our supply chain?

Our AI agent is used to run multiple network design scenarios to estimate the impact of key decisions (e.g., factory openings or closures, international outsourcing) on production costs and environmental impacts.

The target is to offer decision-makers with data-driven insights.

This was the primary time I felt that I may very well be replaced by an AI.

The standard of this evaluation is comparable to that produced by a senior consultant after weeks of labor.

Claude produced it in seconds.

More details on this tutorial,

Do you need to learn more about distribution planning?

Why Lead Time is Necessary?

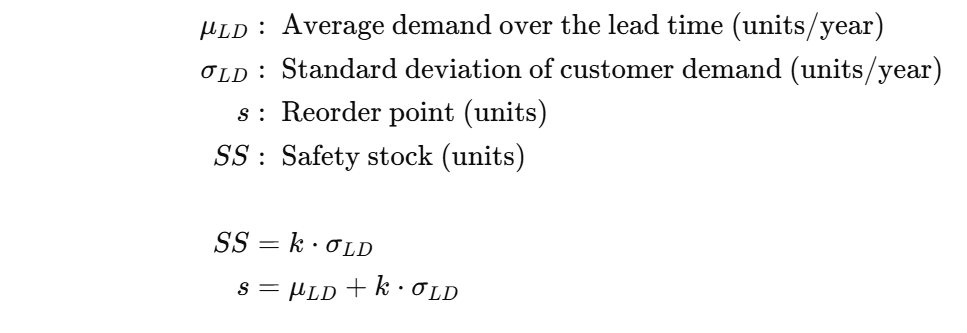

Supply Planners use Inventory Management Rules to find out when to create replenishment orders.

These rules account for demand variability and delivery lead time to find out the optimal reorder point that covers demand until goods are received.

This reorder point will depend on the typical demand over the lead time.

But we are able to adapt it based on the actual performance of the distribution chain.

For more details, see the whole tutorial.

About Me

Let’s connect on LinkedIn and Twitter; I’m a Supply Chain Engineer using data analytics to enhance logistics operations and reduce costs.

For consulting or advice on analytics and sustainable supply chain transformation, be happy to contact me via Logigreen Consulting.