MakinaRocks (CEO Seong-ho Yoon) is an organization representing the domestic ‘industrial artificial intelligence (AI)’ field. It was the one company in Korea to be included within the ‘Top 100 AI Firms’ announced by CB Insights last yr.

Recently, industrial AI has develop into a hot topic in Korea. Not only firms but additionally the Ministry of Trade, Industry and Energy are making strong efforts to introduce AI to the manufacturing industry.

It’s natural that inquiries are pouring into MakinaRocks. The corporate, which began its business in 2017, was the primary to introduce large language models (LLM) to the present computer vision-based manufacturing AI.

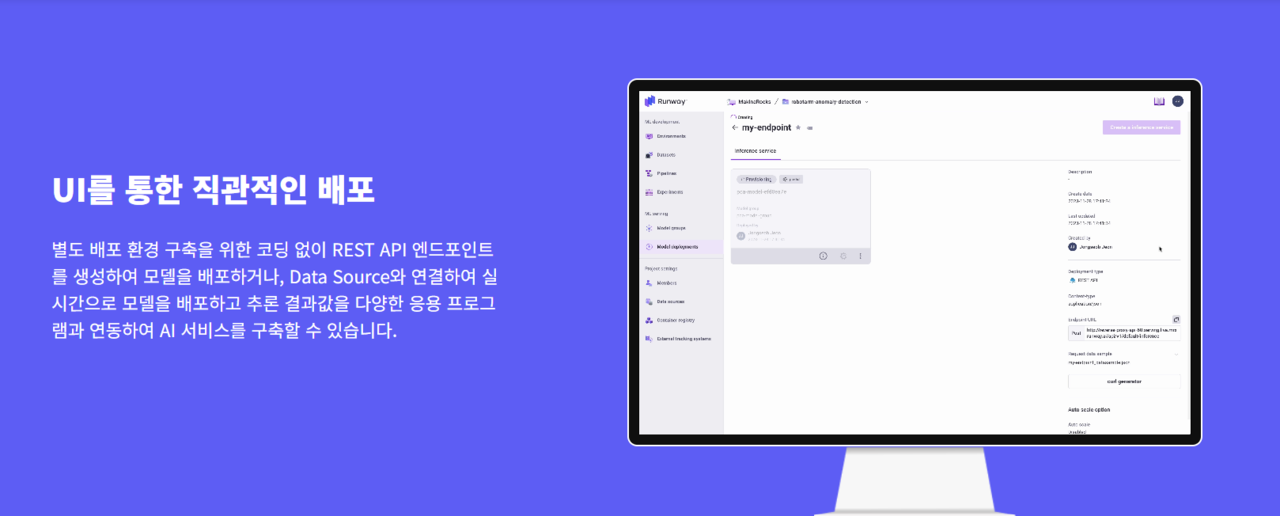

Specifically, as inquiries about ‘manufacturing site specialized LLM’ have been rapidly increasing recently, the corporate announced its intention to appreciate the intelligence of business sites through the signboard AI platform ‘Runway’.

The manufacturing industry, unlike other industries, is sure to be slow in adopting recent technologies like AI. Technological innovation should be achieved while maintaining existing production volumes or scale, and establishing use cases for the sector is of the utmost importance.

Nevertheless, it was reported that inquiries about LLM introduction in manufacturing sites have increased significantly recently. Specifically, the manufacturing industry has completely different application technologies and ideas depending on the sector. MakinaRocks can be focusing all its capabilities on responding to inquiries in recent fields similar to logistics in addition to existing fields similar to automobiles, semiconductors, and batteries.

Specifically, various requirements are being received, including ▲ seek for corporate information, ▲ adding multi-modal creation AI that may create and modify design drawings, and ▲ establishing an LLM that integrates and utilizes metadata, equipment manuals, and maintenance history data.

After all, this company has demonstrated flexible scalability within the manufacturing field. Representative examples include cases where it quickly calculated 1 million variables and derived optimal control logic in 3 days, cases where it reduced energy usage by 3% by reducing the deviation of energy control by employee, and cases where it improved yield by reducing the equipment failure rate from 0.5% to 0.1%.

An organization official said that with the intention to introduce AI to industrial sites, “understanding the unique characteristics of business and manufacturing sites is the start line.” “When most individuals consider introducing AI, they consider constructing customized models through LLM fine-tuning, but that’s the last issue,” he explained.

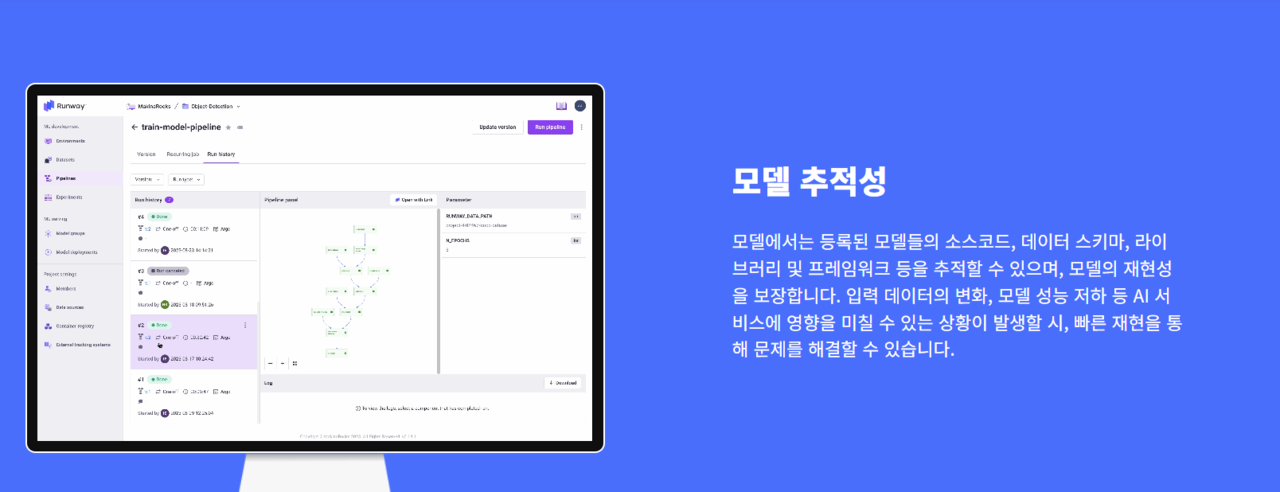

AI performance improvement comes from ‘real-time data learning ability.’ In manufacturing and industrial sites, an enormous amount of information is poured out in real time. With a view to maintain model performance through rapid learning, the feedback loop must even be unobstructed.

Integration with existing systems can be necessary, he said. Existing systems installed in manufacturing sites have already invested huge amounts of capital, from lots of of thousands and thousands to trillions. This can’t be overturned by introducing AI. With a view to reduce the burden on firms, AI should be applied to PLC interfaces (UI) and factory management systems, similar to API linkage.

In the long run, fine-tuning is a structure that should be done after going through this. As well as, fine-tuning is a process that requires numerous resources similar to time, manpower, and money.

With a view to construct an LLM that gives probably the most suitable answers for manufacturing or process sites, MakinaRocks also must develop into an authority in the sector.

As we gained experience in constructing industrial AI, we also differentiated the technologies needed in the sector.

First, ‘Targeted RAG’ was chosen. With a view to comprehensively manage data, facilities, processes, and members of business sites, RAG technology specialized for every database is required. Based on this, MakinaRocks provides an interactive application that may answer various questions in various fields.

Data acquisition can be necessary. Although there’s numerous data in industrial sites, there’s little data to make use of for AI development. He said that synthetic data, which is a recent hot topic, can be not very meaningful. Synthetic data is especially utilized in unstructured data areas similar to voice and image, so it is just not very useful as sensor data in manufacturing sites.

Specifically, since manufacturing sites have already achieved maximum productivity, the variety of ‘abnormal data’ is sure to be significantly smaller than normal data. Because of this, we’re implementing a plan to reinforce the AI model using only normal data.

Even on this process, the traditional standards of the sector are continually changing, which is a characteristic of producing. For instance, when a substance called A reacts with catalyst 1 in a chemical process, 180 degrees Celsius is taken into account normal, but when it reacts with catalyst 2, 150 degrees is evaluated as normal. With a view to routinely reflect such changing situations, the AI platform Runway emphasized that it supports continuous learning (CT).

It also has a digital twin function based on a dynamics model. The digital twin required in industrial sites is more necessary for accurate simulation of machine and equipment status and fast calculation than high-quality graphics. Due to this fact, it is essential to optimize control-combination-scheduling, etc. with a dynamics model.

This feature is clearly useful in the development industry. In truth, it has been introduced as a field where inquiries have been increasing rapidly recently.

▲The predominant requests include the flexibility to integrate LLM with CAD software to design and modify drawings with text input only, ▲the flexibility for engineers to interact and exchange real-time feedback and suggestions based on LLM throughout the design process, and ▲the flexibility to automate the drawing review process to attenuate errors and standardize design quality. The intention is to shorten design time and stop risks.

There are also inquiries about AI adoption within the project management field. That is to routinely manage and optimize project schedules and work flows, efficiently allocate resources similar to manpower, equipment, and materials, and monitor project progress in real time to generate reports, thereby improving work efficiency.

As we reply to such diverse demands, MakinaRocks’ technological advancement is progressing at a distinct level than before. After all, the middle of that is the runway platform.

Yoon Seong-ho, CEO of MakinaRocks, said, “Based on the runway platform, we are going to overcome the constraints of information and lead the intelligence of business sites by utilizing AI re-learning and redistribution, digital twins, etc.”

Specifically, he emphasized, “Our goal is to develop into the neatest AI that surpasses ChatGPT, at the least within the manufacturing field.”

Reporter Jang Se-min semim99@aitimes.com